by ideometry | May 19, 2017 | Uncategorized

This semester, students in the Lean Design and Development School of Technological Entrepreneurship (STE) Masters course are trying something completely new. We have partnered with the Autodesk BUILD Space to give venture teams access to this state-of-the-art maker space. BUILD is located in the innovation district, in the same building as MassChallenge and Continuum’s new studio space. BUILD is a research and development workshop and makerspace designed to spur collaboration and innovation using the latest fabrication technology, software, and materials. Our students are being trained on 3D printers, laser cutters, and other advanced equipment to help them realize their projects. BUILD is also providing materials and technical assistance. This is an amazing opportunity for Northeastern. And we could not be more grateful to Autodesk. In addition to BUILD, we have continued to maintain a close relationship with the Massachusetts College of Art and Design (MassArt). MassArt designers are a part of each team, as are many students from the Engineering Management Masters program in the College of Engineering. Each team has technical skills, business skills, and design skills. The course is taught by myself and Janos Stone, from the College of Arts Media and Design. Together we are taking the journey from opportunity assessment to functioning prototype.

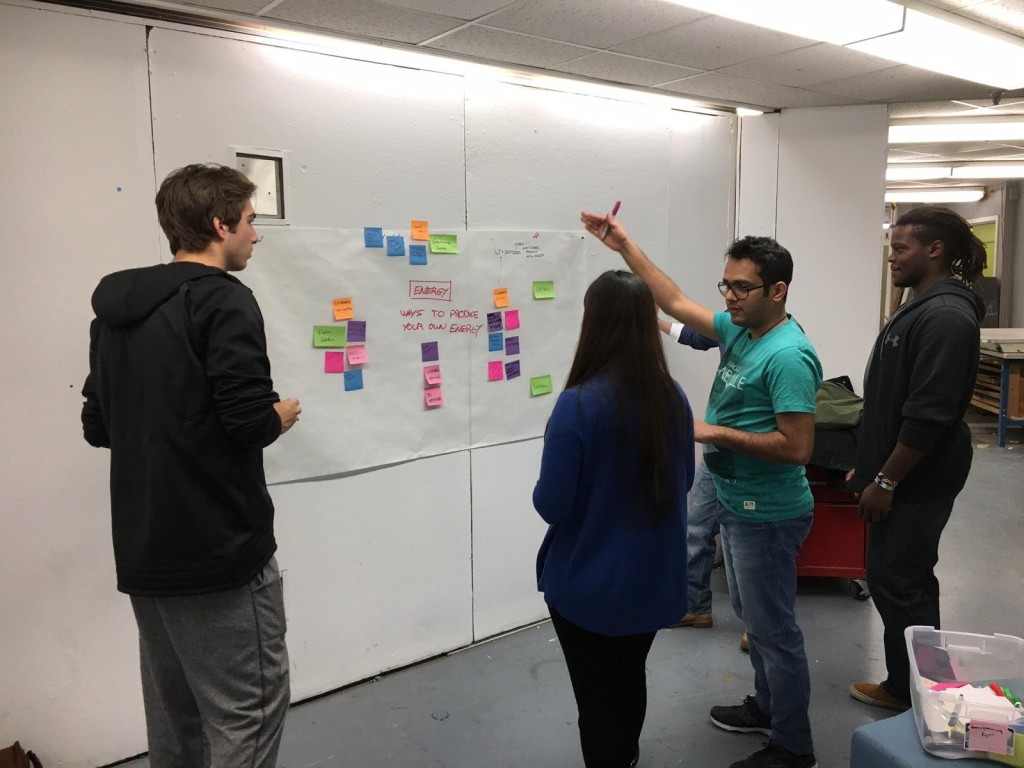

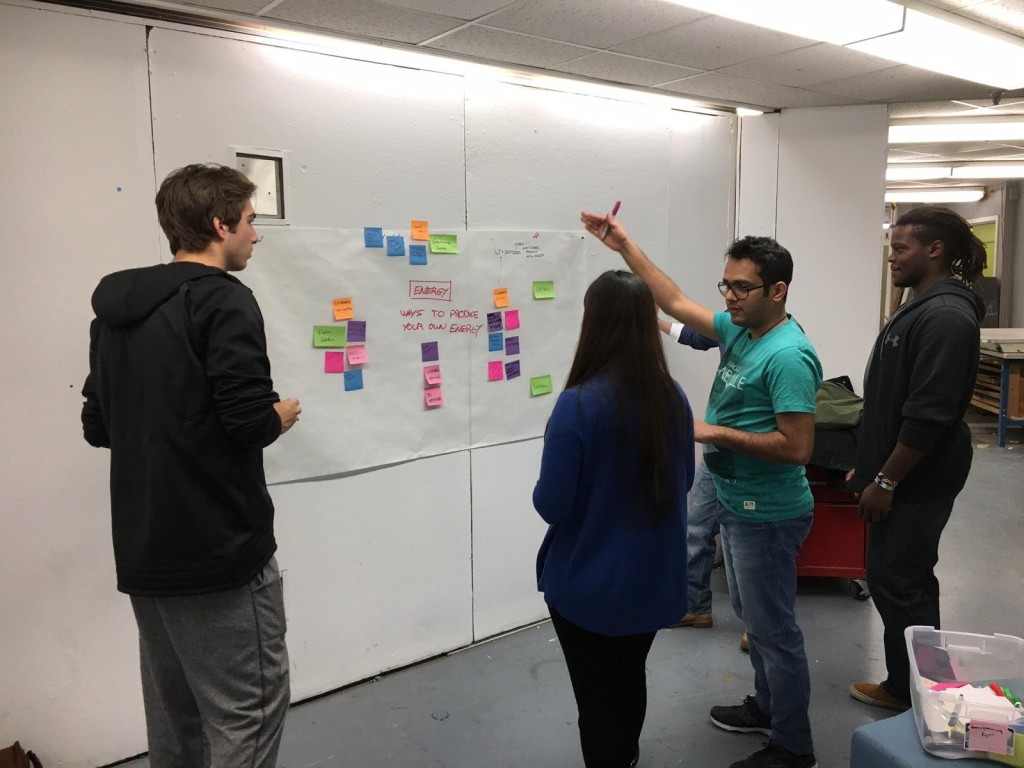

During the first 5 weeks of the course, we approach the projects from a design thinking perspective, developing concepts from opportunities culled from user insights, research and ethnography. Using a structured ideation approach developed in the course; during week 7 leading concepts are selected. Students started their journey with an initial opportunity space ideation session at MassArt on January 31st, shown in the picture below.

The projects are then developed and prototyped with the assistance of the team, their designers, and BUILD over the remaining 7 weeks. A unique aspect of the course is that the students are required to be entrepreneurial. Meaning that they need to bootstrap, scramble and find the resources they need for the very high-level of project quality and realism needed to do well in the course. A limited, intentionally constrained budget is given to each team. This constraint actually encourages bootstrapping, given them some resources, but having them want more. Students are permitted to use outside help, and ask for in-kind support when and where they can. They can learn the tools required, or hire and contract out what they need, just as you would in a small, resource-constrained startup. Examples include prototypes developed using underutilized equipment in a factory in Connecticut, software code contracted in India, free CAD done by roommates, to self taught Raspberry PI development – this is gritty, hands-on global entrepreneurial development in action. In fact, overtime the Northeastern University Center for Entrepreneurship Education (NUCEE) has developed a very defined procedure for handling these courses and associated resources, which are offered for both undergraduate and graduate students. In the future, these courses will be offered in our other campuses such as the Silicon Valley.

This year, we have a focus on sustainability and housing. Already we see some really interesting projects starting to germinate. One of them is 3D rapidly printed refugee housing, designed for Syria and other areas in need. Final project presentations will be given on April 25th at BUILD to Autodesk and other outside experts. If you want to join us, please let me know!

by Tucker Marion | Oct 26, 2016 | Uncategorized

(Also posted in Leaders@ Work: http://www.damoremckimleadersatworkblog.com/developing-an-innovation-education-ecosystem/)

Starting with the Master of Science in Innovation (MSI) program, we have worked over the last year on developing an ecosystem designed to train and develop corporate innovators. Teaching innovation, as we see it, is a continuum spanning from corporate partners and executive education needs to on-ground graduate student cohorts.

When we launched the MSI program in the fall of 2014, we focused on the right side of the continuum – the on-ground graduate program, which covers 10 courses over a year. In the fall of 2016, we entered our third class – the largest and most diverse yet. With average work experience of 12 years and backgrounds spanning from technology services to food innovation, we are excited that our vision for teaching corporate intrapreneurship and innovation is resonating with students and the marketplace. We look forward to seeing where our students take their innovation projects over the course of the next year! (Read about some of our students’ experiences here.)

The second part of our plan is to reach beyond the geographic limits of the Boston area. Markets like San Diego and Austin are prime areas that have high concentrations of technology-focused industry, but not a wide array of options in dedicated innovation business programs.

Additionally, we want to reach global audiences, from Shanghai to Amsterdam to Tel Aviv. Working with Northeastern University’s Global Network, we have developed a completely online version of the graduate MSI program, which we see as the perfect vehicle to reach these global hotbeds of innovation.

Because of the experiential nature of the MSI program, this presented a development challenge. To ensure that the program captured the feel, rigor, and adaptive learning experience of the traditional program, each professor worked closely with an instructional designer to deploy the latest in online learning technology. Each class is unique, with each professor giving her or his signature style and content. There are no teaching assistants – each course is designed, delivered, and run by the on-ground faculty. Each of the courses is segmented into approximately 10 modules, delivered asynchronously with weekly live sessions over the course of nine weeks. And it’s these course modules that lay the groundwork for the next stage of our innovation education ecosystem. The online MSI program runs over a full year, and is launching in January 2017.

Nearly all of D’Amore-McKim’s corporate executive education partners express the same desire for their managers and employees. At the core, that is developing the skills to identify better opportunities, iterate and test potential solutions rapidly, and obtain financing to realize the innovation. The modular design of the online MSI classes allow us to bundle learning modules into custom courses, which in turn can be bundled for graduate certificates for credit.

This gives us three main features:

- Online access to our leading innovation professors and content,

- A platform to develop new skills for employees,

- Adaptive and experiential learning for active innovation projects within the company.

Important to the success of these programs is maintaining D’Amore-McKim’s focus on the power and importance of experiential learning. Try, fail, and learn. For all of our programs, to best realize this we rely heavily on coaching. One-on-one and team focused, this is where the lessons and direct professor feedback hit home.

A recent example of an executive education program we developed was for a leading technology firm. We worked with the firm to design a custom graduate certificate to pair with their internal innovation contest winners – proving real-time education and coaching for a global cohort. We developed the three-course, credit-bearing, online-education certificate program in the spring of 2016, working directly with the firm to ensure the learning objectives meshed directly with their corporate KPIs. The three course topics included innovation and product strategy, rapid design and development, and financing innovation. The content, accessible asynchronously, was augmented by weekly live sessions and special, dedicated coaching sessions. The innovation participants were global – from India to Egypt. Over the course of several months, we were able to shape and hone the innovation projects, help plan and evaluate proof of concepts, and develop a financial plan for the projects to go into implementation phase. Not only did the projects mature at a faster rate, but the student innovators learned key concepts and frameworks that can help them well beyond their current innovation projects.

In summary, the flexibility and modularity we have developed for our innovation programs, we believe, is unrivaled, and it’s gaining the attention of industry leaders. From on-ground traditional cohorts to custom executive education programs, we have developed a suite of offerings that can be specifically tailored to your needs.

Learn more about how our innovation programs may improve your approach and implementation of innovation, from the project level to the C-suite, here.

Tucker Marion is the Sam and Nancy Altschuler Faculty Fellow, Bornstein Endowed Faculty Fellow, and Professor of Technological Entrepreneurship, and he is the faculty director of the MS in Innovation Program. His research and teaching interests include product development processes and tools that foster improved metrics such as time-to-market and commercialization success rates, innovation, technology management and product realization within early-stage companies.

by Tucker Marion | Jan 4, 2016 | Uncategorized

Over the last 10+ years, my fellow researchers and I have spent an enormous time in the field with firm to understand what are the fundamentals of lean innovation. This cuts across new ventures in a variety of industries and also the largest of firms, and how they approach innovation. In compiling lessons learned from our studies of hundreds of firms, here are ten key elements managers need to know about developing a lean innovation process within your organization:

Embrace the Outsider

Corporations can be insular places. And this inward looking focus can make the innovation process sclerotic. We found that those firms that are willing to ‘shake things up’ and bring in outside resources, from project managers and freelance experts to design firms can clear the cobwebs of your innovation project. Think Tony Fadell at Apple – a project manager brought in from the outside, leader of the original iPod team. These outside experts can also be design firms like IDEO or Continuum, designed to help internal projects break the norm. Get a fresh pair of eyes, and not consultants, but hands-on experts to reshape your efforts.

For further reading, check out:

Meyer, M.A. and Marion, T.J. 2010. Innovating for Effectiveness: Lessons from Design Firms. Research-Technology Management, 53(5): 21-28.

Give Lots of Rope

The best innovation teams are those that are empowered, to go inside and outside corporate walls to succeed. In our research, we call these hyper-agile teams, which can leverage the best of what new ventures do best, do anything it takes to move ‘the ball down the field.’ It is essential management give the support and freedom for teams to operate in this fashion. Without it, they are just skunk works teams constrained inside the same corporate bounds.

For further reading, check out:

Marion, T.J. Dunlap, D. and Friar, J.H. 2012. Instilling the Entrepreneurial Spirit in Your R&D Team: What Large Firms Can Learn from Successful Start-ups. IEEE Transactions on Engineering Management, 59(2): 323-337.

Spaces are Important

Corporate sandboxes, innovation spaces and labs. Physical space is important. From the work of Thomas Allen in the 1970’s on workspace communication and collaboration to the design of Apple’s new Cupertino, CA headquarters, the layout and fostering of interaction is tied to communication, knowledge flow, and ultimately innovation success. The most innovative firms care about this, and it generates results. However, just establishing an innovation lab will not spur innovation. There’s a lot more than just the space to consider.

Embrace Collaborative Technology

Wikis, Dropbox’s, cloud-based project management tools, video walls. All of these are technology examples designed to promote communication and collaboration. In our research, the highest performing firms from an innovation project perspective embrace these new tools, and are not afraid to try tools from new ventures. These firms don’t wait for corporate IT, they go out and have teams use what they want. Want a video wall? Hook-up continuous Skype between two offices and see what happens. Traditional Gantt charts not cutting it? Try teamwork.com. In empirical studies, we found that new and social tools have a significant, positive impact on the development process.

For further reading, check out:

Marion, T.J., Barczak, G. and Hultink, E.J. 2014. Do Social Media Tools Impact the Development Phase? An Exploratory Study. Journal of Product Innovation Management, 31(1): 18-29.

Design Beyond Appearance and Usability

Design, like innovation, is somewhat of an overused buzzword. A well-designed product that is beautiful, intuitive, functional, and delivers a world class user experience are now baseline features. Every product and service must have those qualities. What sets apart the truly innovative firm is the drive beyond traditional design into business model and service innovation and integration. Tesla doesn’t just sell an electric vehicle, they sell a new approach to buying, maintaining, servicing, fueling and updating a transportation device. Yes the Model S and X are beautiful and clever, but above everything else, it is the underlying business and service model that is transformative.

Maximize the Minimal

Lean startup methods prescribe the development of functional prototypes to test and validate ideas early, refine, and pivot is needed. Developing a minimally functional prototype (MVP) is a good philosophy, but new technology allows quick and inexpensive development of very credible prototypes. Examples include painted 3D printed prototypes that look and feel like a final product, clean and slick software demos. If you are interfacing with lead users, investors, lead channel partners – spend just a little more time leveraging new prototyping technology to have a more resolved MVP. However, be careful to managing design iterations, as digital technology can foster a culture of endless iterations and churn.

For further reading, check out:

Marion, T.J., Fixson, S.K. and Meyer, M.H. 2012. The Problem with Digital Design. Sloan Management Review, 53(4): 63-68.

Develop Your Support Network

Having a ‘blackbook’ of expert vendors and partners readily available can maximize lean innovation efforts. This select, expert set of vendors and partners that can design, supply, manufacture, fulfill, etc. with blinding speed and quality. And think about having them be local. While firms like Foxconn and other contract manufacturers (CMs) are great for the largest of firms like Apple, don’t overlook smaller firms and individuals. These can substantially lower costs and speed time to test.

For further reading, check out:

Marion, T.J. and Friar, J.H. 2012. Managing Global Outsourcing to Enhance Lean Innovation. Research-Technology Management, 55(5): 44-50.

Lead with your Lead

Bring in your lead potential customers early, and have them be a part of the validation process. These can include OEMs, channel partners, and even investors. Have them become vested in the project and its success. Forty percent of new product launches fail, so increase the success of your innovation process by validating with the people that may write the first purchase order. It’s simple and commonsense, but all too often innovations are developed in a vacuum.

Establish ‘Corn Mounds’

In Native American agriculture, careful planting and arrangement of nourishment for the seeds substantially increased crop yields. The corn mound approach was passed through generations and eventually onto European settlers. For your internal innovation projects, create a culture of R&D corn mounds. Idea hunts, structured seed investment, thoughtful incentives for team involvement, a culture tolerant of failure, and a mentoring and coaching structure. While each individually is important, together they represent a thoughtful approach to innovation cultivation. Money, like water in horticulture, is by itself not a recipe for growth.

Strip the Process

In our investigations of new ventures, the most successful firms eschewed traditional processes like stage-gates, traditional approaches to marketing, and established a culture in which milestones were key. Progress was valued much more heavily than process. For your lean innovation efforts, remove red tape, bureaucracy, and procedures. Focus on milestone management rather than traditional project or program management. A task list in Basecamp.com can be much more effective than a complicated, and always out of date, Gantt chart.

For further reading, check out:

Marion, T.J., Friar, J.H. and Simpson, T.W. 2012. New Product Development and Early-Stage Firms: Two In-Depth Case Studies. Journal of Product Innovation Management, 29(4): 639-654.